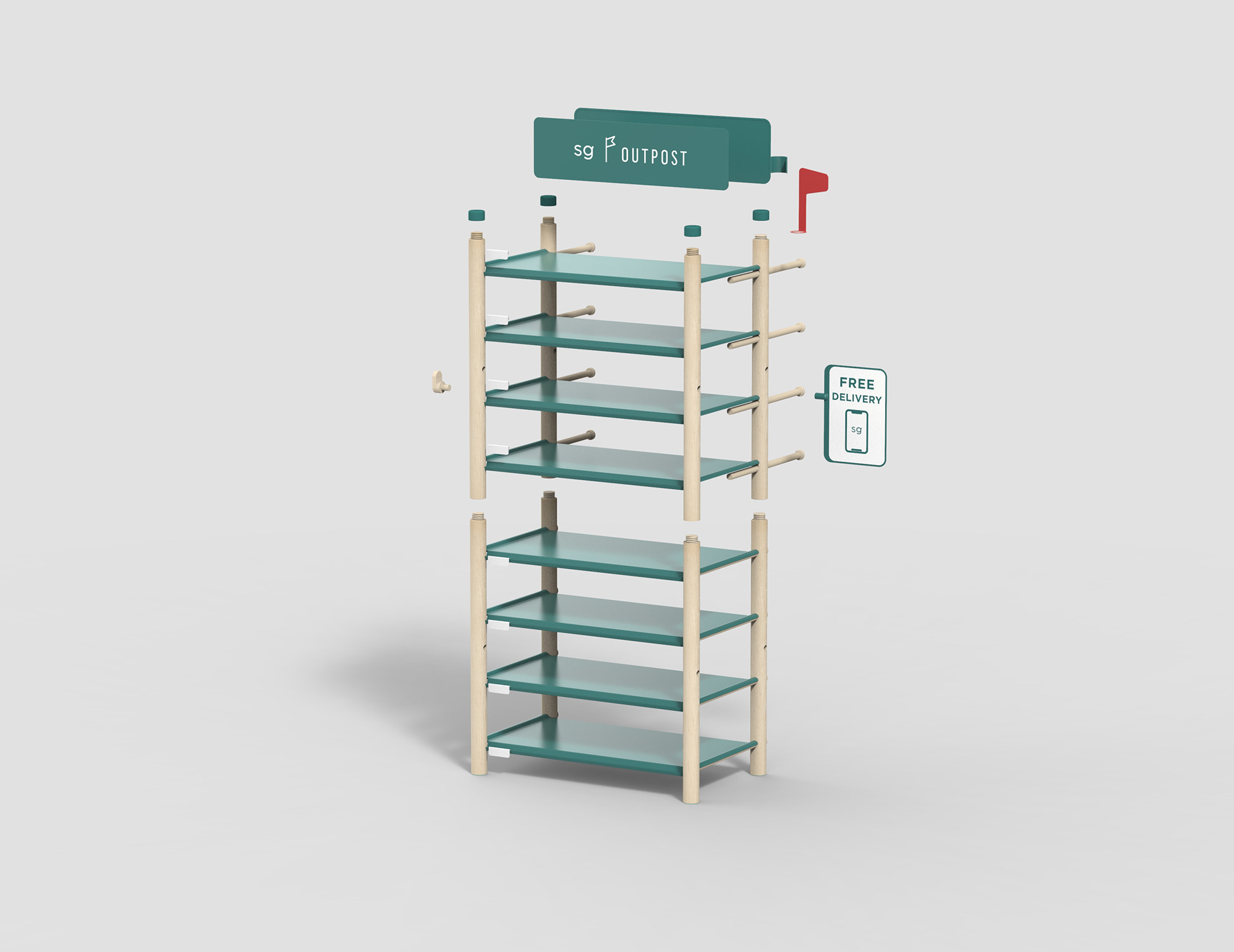

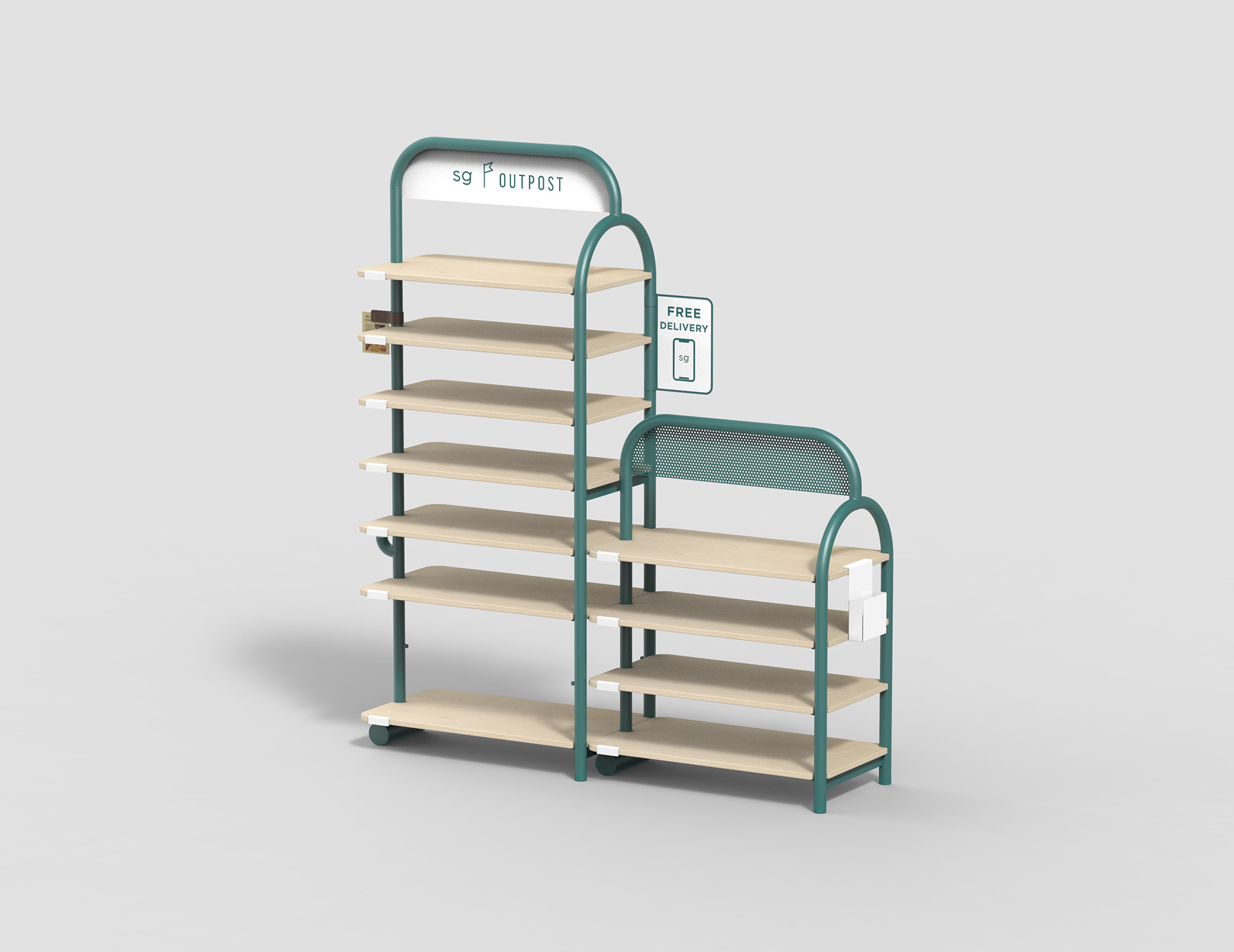

Sweetgreen Outpost Shelf

Outpost is a Sweetgreen offering with free scheduled delivery of the full Sweetgreen menu to specific locations in corporate offices, apartment buildings and retail spaces like your local fitness studio. Customers order their own customized meal via the Sweetgreen app or website, to be delivered to the selected Outpost at a designated drop time.

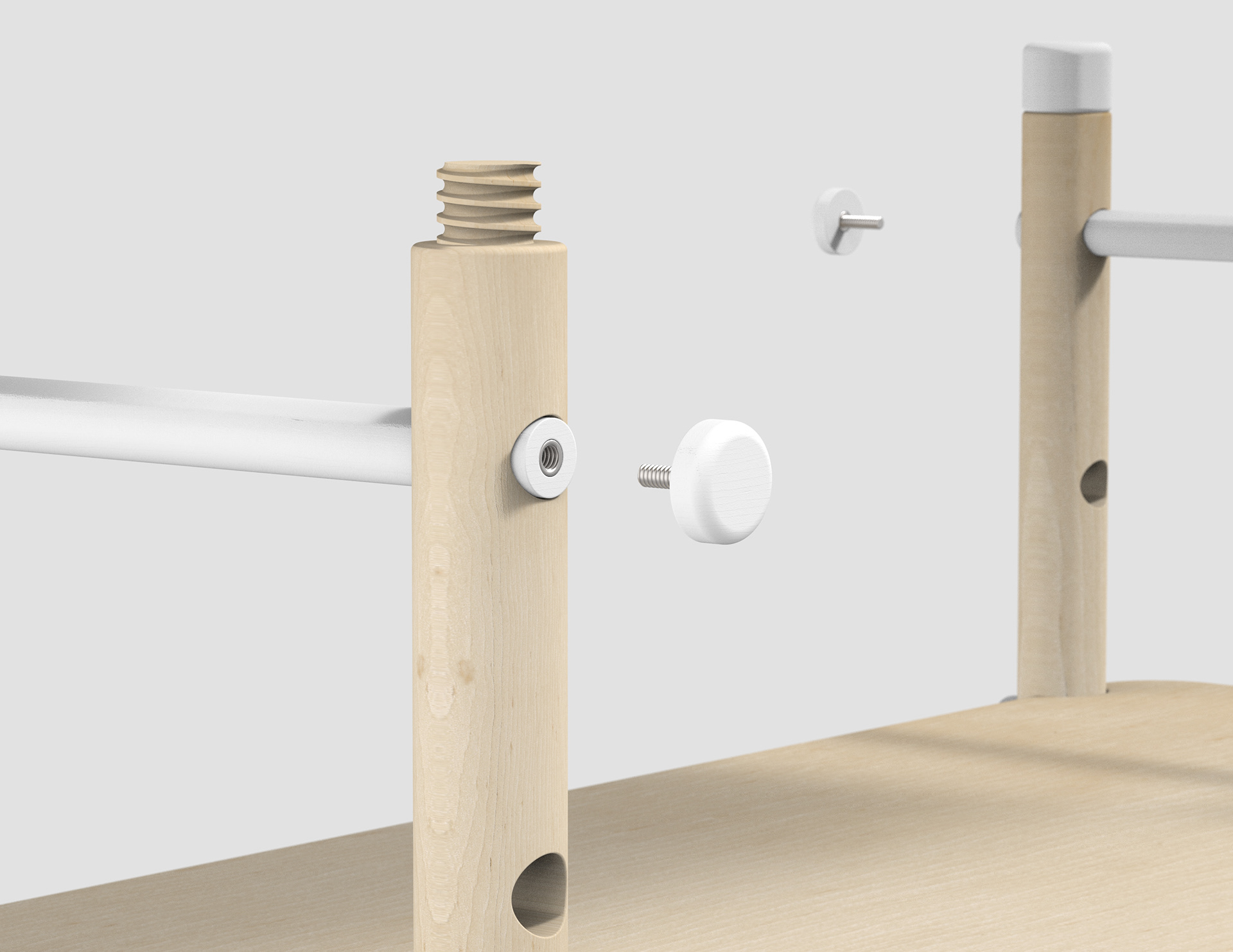

Sweetgreen wanted to redesign the Outpost shelf focusing on modularity, easy installation, affordability, and flat-pack design to attract new customers. The new design is assembled with two "half" shelves that are identical, reducing part counts, simplifying the logistics, and increasing modularity for various spaces. In order to create a more cost effective design, It is also flat-packed into one box with much lighter weight compared to its previous four box pack-out.

I had the opportunity to brainstorm concepts and iterate different rounds of designs with the Outpost team. leading the product development process from the beginning til the end. (Including being a model :)

For Sweetgreen

Photo Credit: Sweetgreen

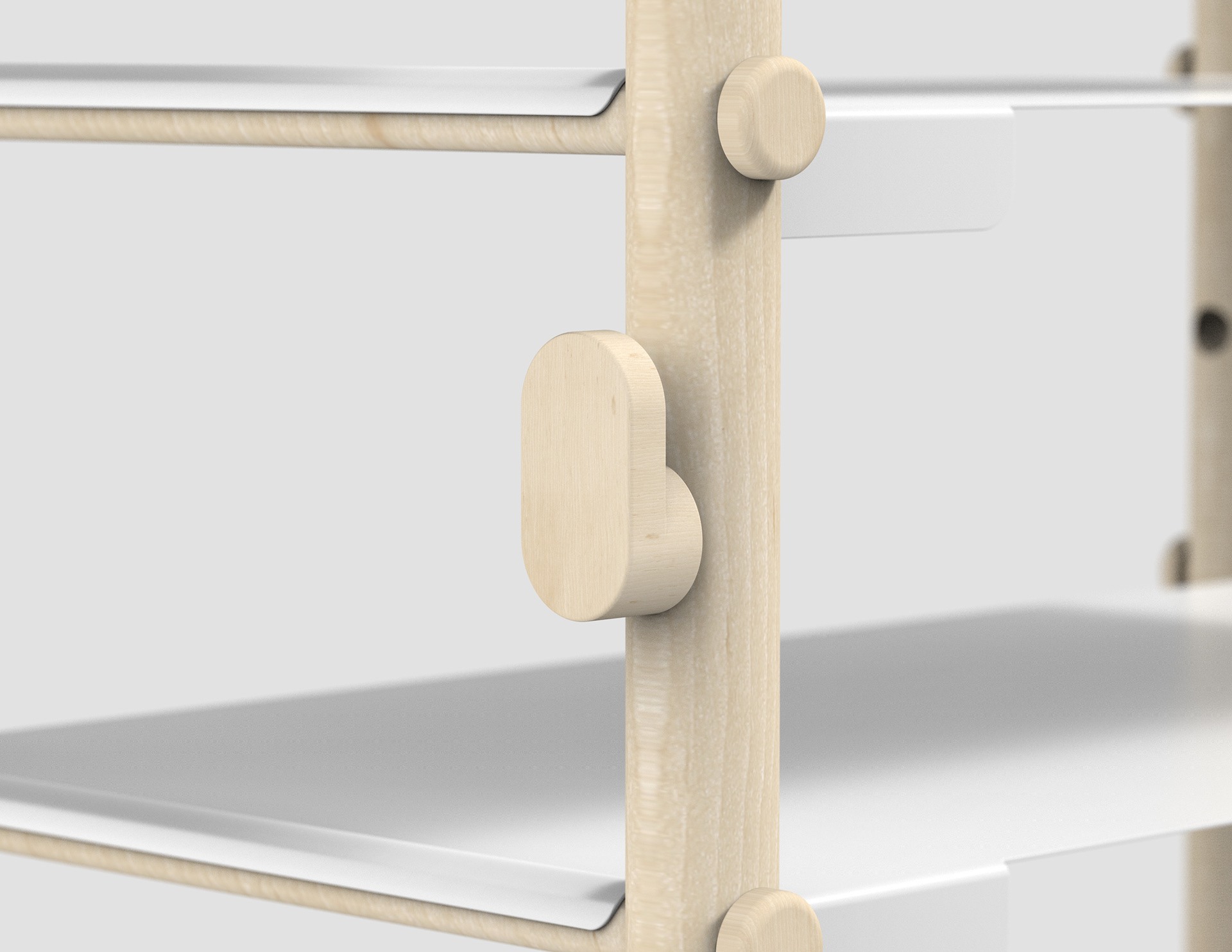

Peg holes provides flexibility in changing shelf height and adding signages and hooks.

Half shelf transforms into a full shelf and can be extended as a modular system.

Process

Previous design

As Outpost scales, Sweetgreen is investing in shelves to increase launch speed and reduce operational complexity to meet customers wherever they are.

Pain points

Complex Installation: Previous shelves require third party installation, which adds dollar cost and operational complexity.

Bulkiness: Due to size, the shelves are difficult and expensive to ship and are sometimes declined by customers, limiting Sweetgreen’s branding opportunity.

Not Flexible: The shelves are not flexible enough in modularity to meet Outpost’s needs as we learn to operate the new business.

Updated design

Lighter design: The total shelf weight decreased by more than 35% using less materials and simpler construction.

Smaller size: The new dimension accommodates customers with small office spaces and/or number of employees.

Less parts: One full shelf consists of two half shelves that are identical in order to make assembly and manufacturing easier.

Reduced carbon footprint : The new design is shipped in one box instead of four with the previous design.

Faster assembly time: 20 min vs 90+ min.

Concept exploration

One pager concepts